CT Safety Surface

When it comes to safety, versatility, and appearance, nothing can compare to the Carpet Tech’s poured-in-place rubber safety surfacing- CT Safety Surface. By combining durable flexible polymer resins with rubber, Carpet Tech can create a highly resilient, skid-resistant surface that is durable, low-maintenance, and easily applicable to a wide variety of commercial and residential flooring.

Benefits of CT Safety Surface

- Anti-fungal

- Anti-bacterial (flooring material is mixed with Microban, an EPA registered disinfectant when installed to resists future growth from staph and other common infections)

- Virtually indestructible

- Slip-resistant (increase safety and decrease liability)

CT Safety Surface is used in a wide variety of applications from water parks, playgrounds, schools, childcare facilities, golf clubs and hotels, private and public housing associations and so much more.

CT Safety Surface Details

- CT Safety Surface is not in a mat form so there are no seams or buckling to be concerned about like with traditional rubber mats. Traffic can resume within 24 hours in most cases.

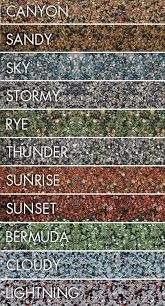

- CT Safety Surface offers limitless options for customization, colors, logos, and designs.

- CT Safety Surface combines high-tech polymer resins with rubber to create a resilient, non-skid surface that is virtually indestructible even with metal spikes. It also offers 16 ft. fall height protection.

- Mixed on-site and troweled in place by our craftsmen to a uniform thickness over your new or existing surface to create a beautiful, seamless finish. We can even include rounded edges and cove base.

- CT Safety Surface is skid-resistant when wet, much like a bath mat which makes rubber safety surfacing perfect for wet deck applications, inside doorways, shops, athletic areas, wheelchair ramp & more.

- CT Safety Surface stretches to accommodate most substrate cracks caused by ground movement and expands and contracts with temperature changes. It can be applied over concrete that has formed cracks.

- CT Safety Surface adheres directly to any solid substrate material including concrete, asphalt, epoxy, stone, brick, wood, steel, tarmac, chipboard, and aluminum. Surface blemishes are easily filled and eliminated without jackhammers or other bothersome equipment.

- CT Safety Surface comes with a 10-year warranty on sun and fade resistance.

CT Safety Surface FAQ

Is CT Safety Surface tested?

CT Safety Surface has undergone many tests over the years including UV stability, critical fall heights, stain resistance, and fungus & bacteria growth. Each test has passed with flying colors. All CT Safety Surface materials have ISO 9002 certification and have been tested by the NSF (National Sanitation Foundation).

How do you safely clean indoor CT Safety Surfacing?

This depends on the system. If it is our sealed system designed for food prep and organic material areas you can use any type of conventional mop to clean the surface. With our porous surface for entryways and locker rooms etc., a steam cleaner is recommended.

Will CT Safety Surface stick to sealed concrete?

CT Safety Surface will stick to most types of sealers such as epoxy and acrylic because our primer coat will make it re-activate and bond to the material.

How will cold temperatures affect CT Safety Surfacing?

CT Safety Surface systems have been proven to cope with the harshest environment including the scorching deserts of Arizona and the harsh winters of Canada.

Can CT Safety Surface be applied in an area that is underwater constantly?

Yes, but it requires annual maintenance and resealing at an additional extra cost.

SCHEDULE YOUR APPOINTMENT TODAY

We are just a click or call away. Get a same-day estimate and fast, easy scheduling.

"*" indicates required fields

SCHEDULE YOUR APPOINTMENT TODAY

We are just a click or call away. Get a same-day estimate and fast, easy scheduling.

"*" indicates required fields

CT Safety Surface

When it comes to safety, versatility, and appearance, nothing can compare to the Carpet Tech’s poured-in-place rubber safety surfacing- CT Safety Surface. By combining durable flexible polymer resins with rubber, Carpet Tech can create a highly resilient, skid-resistant surface that is durable, low-maintenance, and easily applicable to a wide variety of commercial and residential flooring.

Benefits of CT Safety Surface

- Anti-fungal

- Anti-bacterial (flooring material is mixed with Microban, an EPA registered disinfectant when installed to resists future growth from staph and other common infections)

- Virtually indestructible

- Slip-resistant (increase safety and decrease liability)

CT Safety Surface is used in a wide variety of applications from water parks, playgrounds, schools, childcare facilities, golf clubs and hotels, private and public housing associations and so much more.

CT Safety Surface Details

- CT Safety Surface is not in a mat form so there are no seams or buckling to be concerned about like with traditional rubber mats. Traffic can resume within 24 hours in most cases.

- CT Safety Surface offers limitless options for customization, colors, logos, and designs.

- CT Safety Surface combines high-tech polymer resins with rubber to create a resilient, non-skid surface that is virtually indestructible even with metal spikes. It also offers 16 ft. fall height protection.

- Mixed on-site and troweled in place by our craftsmen to a uniform thickness over your new or existing surface to create a beautiful, seamless finish. We can even include rounded edges and cove base.

- CT Safety Surface is skid-resistant when wet, much like a bath mat which makes rubber safety surfacing perfect for wet deck applications, inside doorways, shops, athletic areas, wheelchair ramp & more.

- CT Safety Surface stretches to accommodate most substrate cracks caused by ground movement and expands and contracts with temperature changes. It can be applied over concrete that has formed cracks.

- CT Safety Surface adheres directly to any solid substrate material including concrete, asphalt, epoxy, stone, brick, wood, steel, tarmac, chipboard, and aluminum. Surface blemishes are easily filled and eliminated without jackhammers or other bothersome equipment.

- CT Safety Surface comes with a 10-year warranty on sun and fade resistance.

CT Safety Surface FAQ

Is CT Safety Surface tested?

CT Safety Surface has undergone many tests over the years including UV stability, critical fall heights, stain resistance, and fungus & bacteria growth. Each test has passed with flying colors. All CT Safety Surface materials have ISO 9002 certification and have been tested by the NSF (National Sanitation Foundation).

How do you safely clean indoor CT Safety Surfacing?

This depends on the system. If it is our sealed system designed for food prep and organic material areas you can use any type of conventional mop to clean the surface. With our porous surface for entryways and locker rooms etc., a steam cleaner is recommended.

Will CT Safety Surface stick to sealed concrete?

CT Safety Surface will stick to most types of sealers such as epoxy and acrylic because our primer coat will make it re-activate and bond to the material.

How will cold temperatures affect CT Safety Surfacing?

CT Safety Surface systems have been proven to cope with the harshest environment including the scorching deserts of Arizona and the harsh winters of Canada.

Can CT Safety Surface be applied in an area that is underwater constantly?

Yes, but it requires annual maintenance and resealing at an additional extra cost.